- Home

- Who We Are

- Products

-

Brands

-

Products by Measure

- Vibration Analyzers

- Peristaltic Pumps

- Airflow

- CO Carbon Monoxide

- Geiger counters

- Destiladores

- Spectrophotometry

- Sterilization

- Fluorescence

- GEOTECHNICS

- Soil Moisture

- Leaf area index

- Rain Gauge

- Meteorology

- Water Level

- O2 Oxygen

- pH

- Differential Pressure

- Radiation

- Salinity/Conductivity

- Telemetry

- Air Speed

- Relative Humidity

- Veterinary

- FUEL CELL HARDWARE

- Network Analyzers

- Calibrators

- WATER FLOW

- Color / Colorimeter

- Particle Counters

- Wind Direction

- Spectrometry

- Evapotranspiration

- Photosynthesis

- Cracks in Buildings

- Pipes Inspection

- Quantum Light

- Movement & GPS

- Diesel Level

- Oxígeno Disuelto DO

- Atmospheric Pressure

- Radon

- Sap/Sap Flow

- Temperature

- AIR QUALITY

- Ammonia

- Chlorophyll

- Conductivity in Soil

- Dendrometers

- Electrochemistry

- Spectroradiometry

- Pharmacy & Medicine

- GAS (ANALYZERS)

- Leaf Wetness

- Idc (DC Current)

- KW & KW/H

- PAR Light

- Nitrate

- Occupation and Time

- Particle Meters

- Soil Water Potential

- Pulses

- Flavor/Taste/Acidity

- Sodium

- Turbidity

- VOC

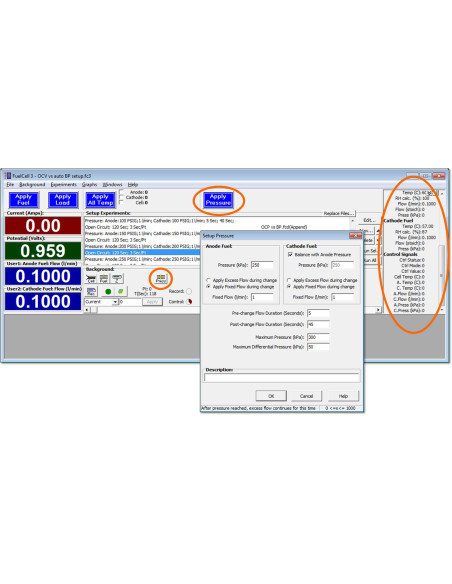

AutoBP Auto Back Pressure Unit

The Auto Back Pressure Unit works with Scribner Associates’ 840, 850e and 890e Fuel Cell Test Systems for accurate, independent control and measurement of anode and cathode pressure through the FuelCell® software.

- Automatic control of back pressure from 10 to 300 kPag (1.5 to 44 psig)

- All stainless steel construction – regulators, condensate collection tanks, tubing and fittings

- Dual channel with isolated flow paths & fan-cooled heat exchangers

- High-precision, water-tolerant regulators and large flow paths

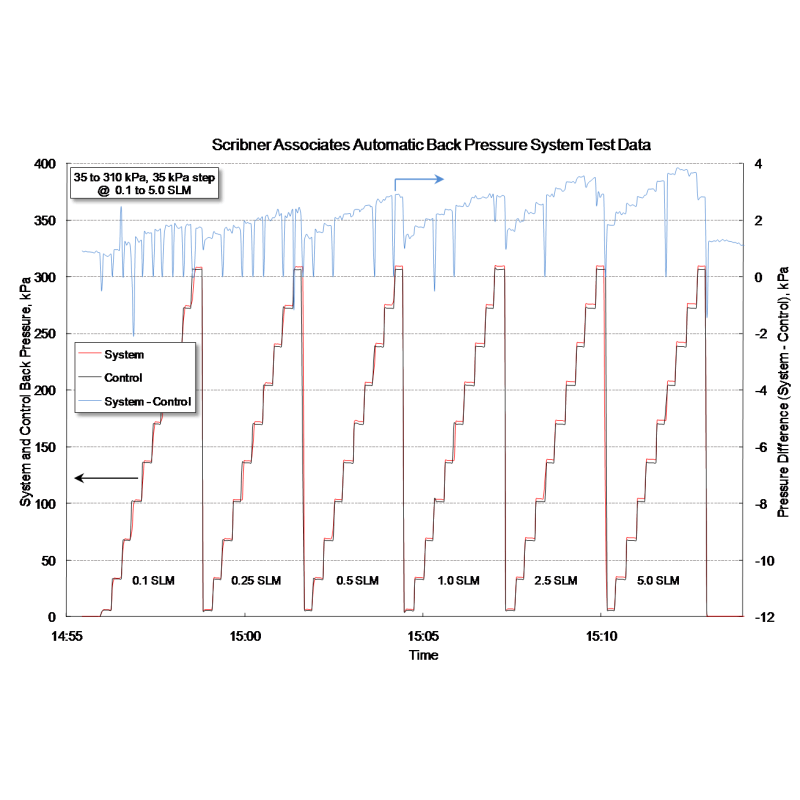

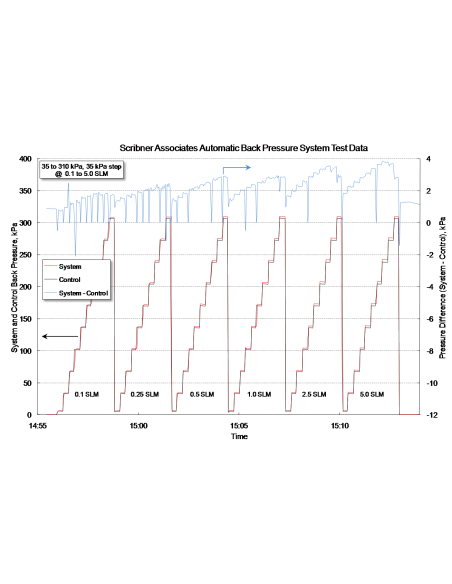

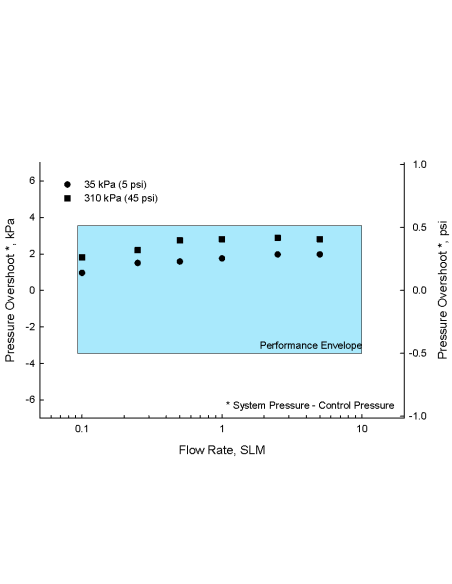

- Accurate pressure control (±3.5 kPa or 0.5 psi) & stability from 0.1 – 10 SLM

- Precision pressure transducers

- Operation with gas with dew point up to 120 °C at 10 SLM

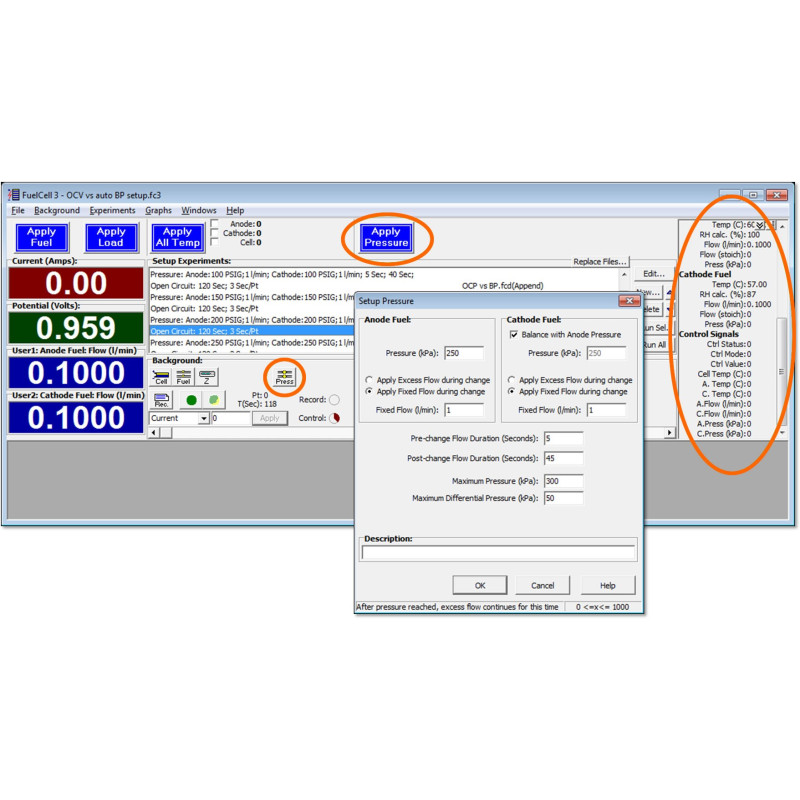

- Flexible pressure control through FuelCell®

- Independently control or balance anode & cathode pressure

- Control excess gas flow during pressure increases

- Maximum back pressure & differential pressure set points and alarm triggers

- Program pressure profiles using Change Pressure Experiment or Arbitrary Control Experiment

| Specifications: | Details |

|---|---|

| Back Pressure Control: | 10 – 300 kPag (1.5 – 44 psig) |

| Control Accuracy: | ±3.5 kPa (±0.5 psi) |

| Range: | 0 - 300 kPag (0 – 44 psig) |

| Measurement Accuracy: | 2.5 kPa (0.35 psi) |

| Time to achieve normal P-to-P Set-point (when not flow rate limited): |

< 10 s |

| Overshoot: | < 10 kPa (1.5 psi) |

| Flow Rate: | 0.1 - 10 SLPM |

| Inlet Gas Temperature & Dew Point: | Up to 120 °C |

| Pilot Gas Supply: | Clean, dry air or N2, 345-480 kPa (50-70 psi), ≤0.8 SLPM |

| Dimensions: | 33 W x 33 D x 64 H (cm), 13 W x 13 D x 25 H (inch) |

| Operating Temperature: | 5 - 35 °C |

| Power Requirements: | 100 - 240 V, 50 - 60 Hz, 2 A |