No products

Prices are tax excluded

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

WD-E3 WinDIAS Leaf Image Analysis System

New

- WinDIAS 3 Entry Level System WD-E3: Entry Level Image Analysis System.

Includes WinDIAS 3 Software with A4 flatbed scanner (typically >1000 dpi) (230V/50Hz and 110V/60Hz).

- Advanced leaf area meter

- Measures area, perimeter, length, width, object count, etc.

- Measures diseased, healthy and pest-damaged leaf area

- Point and click colour selection

- Conveyor option for high speed leaf processing

New:

- LED lighting with adjustable brightness

- Improved seed counting capability

- Enhanced Area of Interest drawing tool

- Consulta este producto

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

| Type of Instrument | Image Analysis System |

| The instrument measures: | Leaf area |

The recently upgraded WinDIAS 3 Leaf Image Analysis System provides fast, accurate measurement of leaf area and leaf features.

This makes the WinDIAS 3 ideal for plant pathology and phenotyping applications.

WinDIAS’s analysis features are well suited to applications where precise colour discrimination is critical.

Enhanced Area of Interest drawing tool

WinDIAS is a leaf image analysis system with multiple functions.

It can measure the healthy, diseased, and pest-damaged area of large batches of leaves. It can also measure leaf perimeter, length and width - and count objects, such as seeds.

Delta-T Devices was one of the first companies to develop leaf imaging technology for disease area estimation. The WinDIAS 3 leaf area measurement system builds on that expertise, making use of high-resolution camera and scanner technology to provide researchers with an analysis tool that is powerful and yet easy to use.

The WinDIAS system is available in three versions – Entry Level System (with A4 scanner), Standard System (with video camera), and Rapid System (which adds a conveyor belt unit, and can process up to 800 leaves an hour).

WinDIAS features

Rapid thresholding

Three thresholds can be set, each based on a different user-defined range of colours. The primary threshold is used for the main zones of interest in the image, e.g. healthy areas. The secondary and tertiary thresholds are used for other zones, e.g. diseased or variegated areas. Thresholds are set by a simple point and click with the mouse in a region of interest. The areas selected are immediately visible as overlays on the image.

Measurement and editing

WinDIAS analyses the thresholded regions to measure area, perimeter, length, width, circularity, elongation and shape factor. Calibration is carried out against a ruler. Images can be edited on-screen, enabling the user to retouch boundaries, separate objects that overlap, remove undesirable “noise” and holes, add or erase lines or rectangles, and fill bounded areas in any colour.

Object count

Seeds, needles, or other small objects can be quickly counted by WinDIAS (even when touching). Colour thresholding enables easy discrimination of different types of object, or disease spots. Dust and debris can be excluded by defining a minimum object area.

Exchange of data and images

WinDIAS imports images in bmp, jpg and tif formats, and results can be saved as txt files for easy import into Excel. For reporting and further analysis, all results and images from WinDIAS are easily exchanged with other Windows applications.

Fast batch processing of image files

WinDIAS can automatically analyse large numbers of leaf images by operating as a virtual conveyor. This feature saves a great deal of time when processing images acquired in the field or when sent in for processing from a remote research lab. Images in bmp, jpg, or tif format are all suitable for processing.

Batch processing mode is simple to use – just select the folder holding the target images. WinDIAS will then automatically load each image in turn, measure it, and save the results back into the same folder.

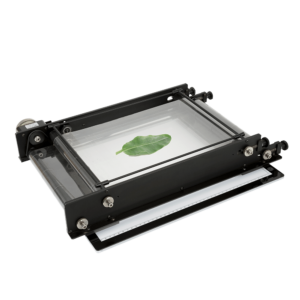

Conveyor Belt Unit

The Conveyor Belt Unit comes as default with the Rapid System (or can be purchased separately to upgrade the Standard System). It enables rapid throughput of large numbers of leaves (up to 800 per hour) and also allows for measurement of intact long leaves. e.g. maize.

The Conveyor Belt Unit’s twin transparent belts carry the leaves past the downward facing video camera – each leaf being automatically captured, analysed and processed. A lightbox provides background illumination and top lighting optimises colour discrimination.

Leaves which are too long to fit within the field of view of the video camera can be analysed with the aid of the Conveyor Belt Unit. Typically, a leaf 30 cm long by 2 cm wide can be measured in 4 seconds.

Reference Target Set type WD-RTS-1

The WD-RTS-1 comprises precision reference images (for thickness, perimeter and particle count etc.) supplied on acetate film and a colour rendition chart. The references can be used to check the WinDIAS colour selection default threshold, to check or adjust the colour camera, and to check or re-establish lighting conditions.

Applications:

Agronomy, plant physiology and phenotyping:

WinDIAS provides a flexible resource with many laboratory applications – from simple leaf area measurement to the analysis of complex distributions of colour. The addition of the Conveyor Belt Unit accessory opens up further applications – see above.

Forestry

WinDIAS can be used with both broadleaf and coniferous species. The surface area of pine needles can be estimated by multiplying the projected area by a conversion factor.

Plant pathology and crop protection

WinDIAS is optimised for the rapid analysis of area by colour difference, creating many applications in plant pathology and plant protection. Examples include: necrosis caused by fungi and bacteria, leaf tip burn and leaf spotting, nutrient deficiency symptoms, viral infection and leaf senescence.

Other applications

WinDIAS is very versatile. For example, it can assist with the analysis of aerial photos to estimate ground cover, and can be used with a suitable zoom lens or a USB microscope to measure and count very small objects.

LAI – Leaf Area Index

There are more ways of getting to LAI than just measuring individual leaves. We also offer SunScan and HemiView – two innovative techniques for estimating LAI non-destructively in crop and forest canopies.

| Entry Level System | Standard System | Rapid System | |

| Throughput (leaves/hour) | ~50 (typical, depends on leaf size) | ~150 | ~800 |

| Resolution | Typically >1000 dpi | 2048 x 1536 pixels | 1280 x 1536 pixels |

| Minimum object size | ~ 0.02 mm | 1 pixel | 1 pixel |

| Maximum sample area | 297 x 210 mm (A4) | 300 x 295 mm | 250 x 290 mm (conveyor) 250 x >1000 mm (long leaf mode) |

| Accuracy area measurement [1] | ± 1% typical | ± 4% typical | ± 4% typical |

| Accuracy diseased/healthy area | contrast dependent | contrast dependent | contrast dependent |

| Accuracy long leaf mode | not applicable | not applicable | ± 5% typical |

| Calibration static measurements | against an object of known length, e.g. a ruler | against a ruler | |

| Calibration conveyor measurements | not applicable | against a target of known area | |

| Conveyor belt speeds | not applicable | not applicable | 60/100/140/190 mm/s (20% faster for 60Hz model) |

| Colour depth | WinDIAS works in 24bit colour space (16 million colours) | ||

| Image file formats | .jpg, .bmp and .tif (WinDIAS is compatible with many scanners and cameras that are TWAIN compliant) | ||

| Operating system and drivers | Windows 7, 8 and 10 (32 and 64 bit) | ||

Specification apply to a WinDIAS system using standard components supplied by Delta-T Devices. Use of other cameras, lighting systems or camera stands may reduce accuracy due to reflections, poor contrast, or image distortion.

Main components and software

- CB-230/60 – Conveyor Belt Unit 230V/60Hz. Incl material to make 10 prs belts.

- CB-230/50 – Conveyor Belt Unit 230V/50Hz. Incl material to make 10 prs belts.

- WD-RTS-1 WinDIAS Reference Target Set

Spares and consumables

- WD-AS1 Acrylic Sheets for WinDIAS

- CBSP1 – Spare Conveyor Belt Unit Material (Enough to Make 10 Pairs)

- CBSP2 – Spare Conveyor Belt Unit Material (Enough to Make 50 Pairs)

- CBSP3 Full set of “O” rings and two drive bands for Conveyor Belt Unit

Power options

- PC-IN Mains lead, India/S Africa plug to IEC connector

WinDIAS system options

Researchers can specify a WinDIAS leaf area meter system that suits their particular requirements.

Rapid System

A powerful and complete leaf area system that can handle very long leaves and measure up to 800 leaves per hour. Includes video camera, camera stand, overhead lighting, WinDIAS Software and Conveyor Belt Unit.

Standard System

Identical to Rapid System but without Conveyor Belt option. Typically processes 150 images per hour.

Entry Level System

Comprises WinDIAS Software and A4 flatbed scanner. Typically processes 50 images per hour (at high resolution).

110V Systems

The Entry Level and Standard systems are both dual voltage 110V/230V and can operate at 50Hz/60Hz. However, the Rapid system is limited to 230V 50HZ or 220V 60Hz. This is because we cannot supply 110V versions of the Conveyor Belt Unit.

| WD-R3-230 | WinDIAS 3 Rapid System (230V/50Hz) |

| Rapid Image Analysis System (230V/50Hz). Includes WinDIAS 3 Software, | |

| camera stand, camera, camera lens, LED lightbox, LED overhead lights, | |

| pack of acrylic sheets and Conveyor Belt Unit. | |

| Requires correct IEC mains lead, type PC-UK, PC-EU, PC-US, PC-IN, PC-CN. | |

| NB: IEC mains lead cable must be ordered separately - see below. | |

| WD-S3-230/110 | WinDIAS 3 Standard System (230V/110V) |

| Standard Image Analysis System (230V/110V). Includes WinDIAS 3 | |

| Software, camera stand, camera, camera lens, LED lightbox, | |

| LED overhead lights and pack of acrylic sheets. | |

| Requires correct IEC mains lead, type type PC-UK, PC-EU, PC-US, PC-IN, PC-CN | |

| NB: IEC mains lead cable must be ordered separately - see below. | |

| WD-E3 | WinDIAS 3 Entry Level System |

| Entry Level Image Analysis System. Includes WinDIAS 3 Software | |

| with A4 flatbed scanner (typically >1000 dpi) (230V/50Hz and 110V/60Hz). |