- Home

- Who We Are

- Products

-

Brands

-

Products by Measure

- Vibration Analyzers

- Peristaltic Pumps

- Airflow

- CO Carbon Monoxide

- Geiger counters

- Destiladores

- Spectrophotometry

- Sterilization

- Fluorescence

- GEOTECHNICS

- Soil Moisture

- Leaf area index

- Rain Gauge

- Meteorology

- Water Level

- O2 Oxygen

- pH

- Differential Pressure

- Radiation

- Salinity/Conductivity

- Telemetry

- Air Speed

- Relative Humidity

- Veterinary

- FUEL CELL HARDWARE

- Network Analyzers

- Calibrators

- WATER FLOW

- Color / Colorimeter

- Particle Counters

- Wind Direction

- Spectrometry

- Evapotranspiration

- Photosynthesis

- Cracks in Buildings

- Pipes Inspection

- Quantum Light

- Movement & GPS

- Diesel Level

- Oxígeno Disuelto DO

- Atmospheric Pressure

- Radon

- Sap/Sap Flow

- Temperature

- AIR QUALITY

- Ammonia

- Chlorophyll

- Conductivity in Soil

- Dendrometers

- Electrochemistry

- Spectroradiometry

- Pharmacy & Medicine

- GAS (ANALYZERS)

- Leaf Wetness

- Idc (DC Current)

- KW & KW/H

- PAR Light

- Nitrate

- Occupation and Time

- Particle Meters

- Soil Water Potential

- Pulses

- Flavor/Taste/Acidity

- Sodium

- Turbidity

- VOC

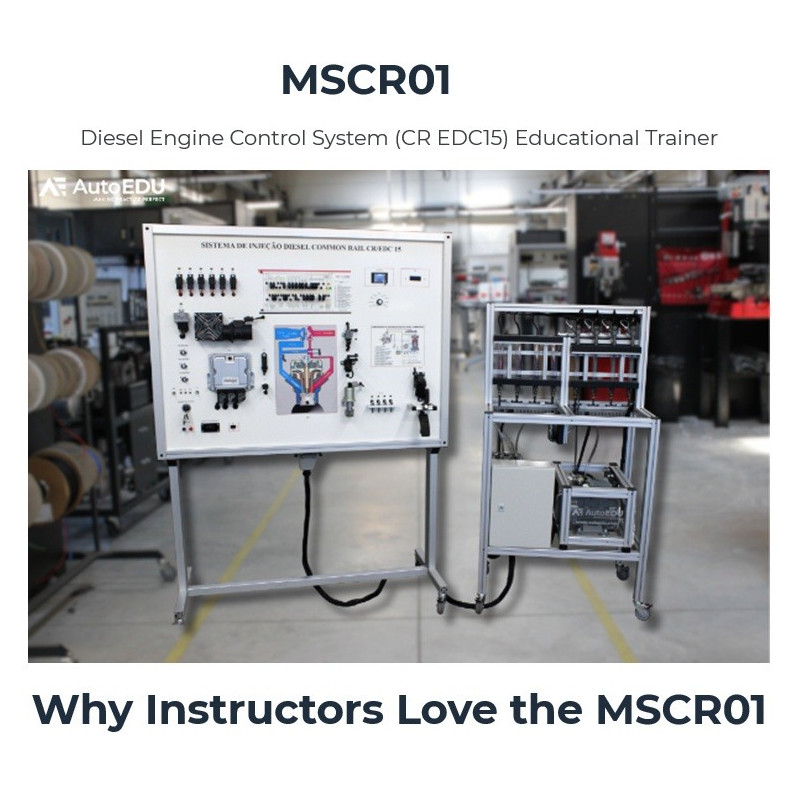

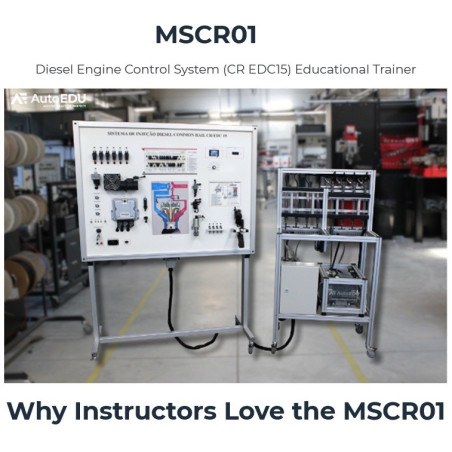

AutoEDU MSCR01 Diesel engine control system CR/EDC 15 Educational Trainer

◆ Explore our cutting-edge Common Rail trainer featuring the Bosch EDC 15C3-4.1 engine control system, seamlessly integrated into a mobile aluminum frame. This specialized training board-simulator is meticulously crafted to enhance the comprehension of diesel injection Common Rail systems for technical students.

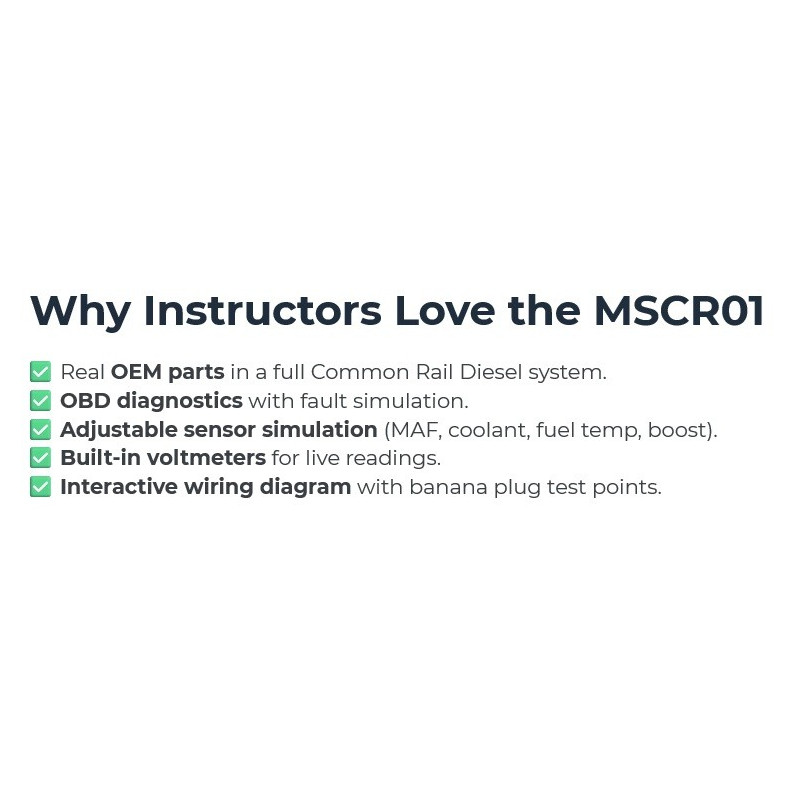

Key Features:

◆ Fully functional Common Rail system

◆ Convenient diagnosis via OBD 16-pole diagnostic socket

◆ Accessible open contacts for measuring system components and circuits

◆ Realistic fault code simulations

AutoEDU MSCR01 Diesel engine control system CR/EDC 15 Educational Trainer

I accept privacy policy rules

► Immerse yourself in hands-on learning with our state-of-the-art Common Rail trainer, designed to provide a comprehensive understanding of engine control systems and diesel injection technology.

► The educational training board is meticulously crafted with genuine Renault OEM components. Powered by the integrated Bosch EDC 15 engine control system, this board provides a comprehensive showcase of the diverse operation modes of the direct fuel injection system. The Common Rail training board-simulator stands as an exceptional educational tool, offering students a unique opportunity to delve into the intricacies of engine control systems.

Introducing our integrated engine control system featuring diesel Common Rail direct injection. This comprehensive stand comprises two parts: one designed to showcase the high-pressure pump and injectors, and the other to illustrate the electronic engine management system. Both components are seamlessly interconnected, operating as a unified system.

Key Features:

-

High Pressure Fuel Supply System Demonstration: Monitor the operation of the high-pressure pump and injectors, observe injected fuel quantity, fuel back leak, and spray pattern quality.

-

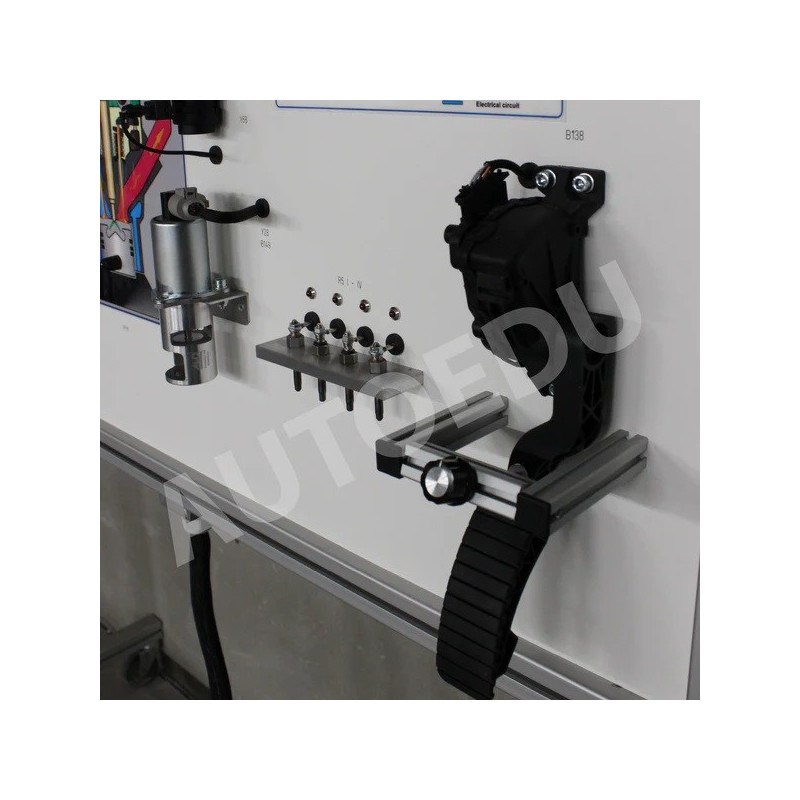

Adjustable Air Flow Rate Simulator: Simulate the function of the mass-air flow meter and air temperature sensor with manual adjustment of the engine crankshaft speed.

-

Integrated Sensor Parameter Adjustment: Modify parameters of the engine temperature sensor and intake air pressure sensor using integrated simulators.

-

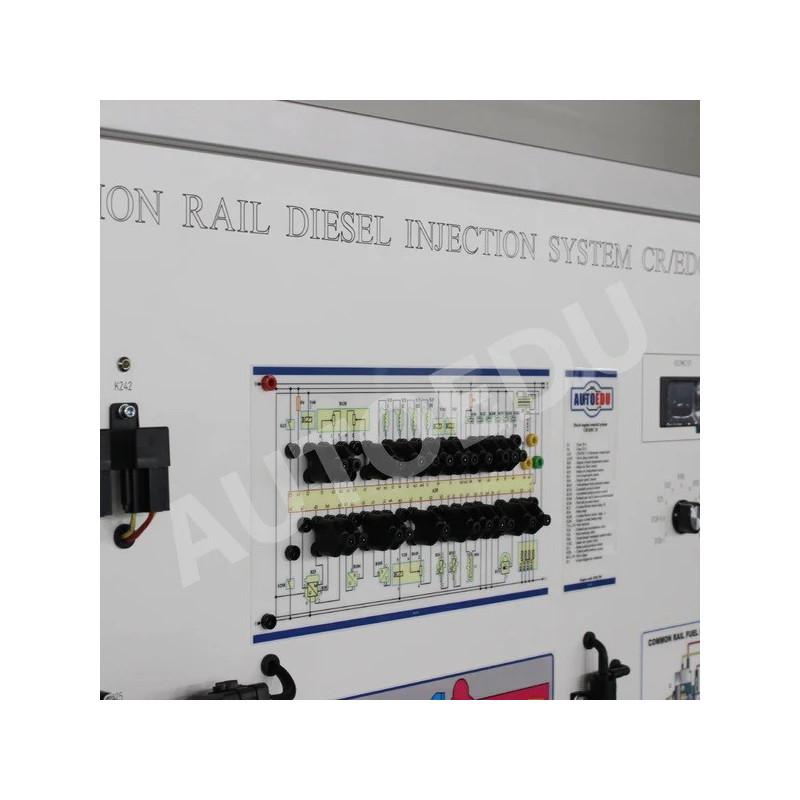

Electric Wiring Diagram with Banana Plug Jumpers: Equipped with a wiring diagram featuring built-in banana plug jumpers for easy measurements and simulation of system fault codes.

-

Real-time Monitoring: Monitor the changing operation mode of each system component, providing valuable insights into system performance.

-

Fault Simulation: Simulate over 20 faults by disconnecting banana plug jumpers, allowing hands-on experience in diagnosing and addressing issues.

-

Integrated TFT Voltmeter: Display voltage readings for electronic system components, including:

• APPS1 Accelerator Pedal Position Sender I

• APPS2 Accelerator Pedal Position Sender II

• ACT Air Charge Temperature Sensor

• MAF Air Mass Flow Meter

• FPS Fuel High-Pressure Sensor

• MAP Intake Manifold Pressure Sensor

• EGR Exhaust Gas Recirculation Potentiometer

• CTS Engine Coolant Temperature Sensor

• FTS Fuel Temperature Sensor

Immerse yourself in a comprehensive learning experience with our integrated engine control system, designed to enhance understanding and practical skills in diesel Common Rail direct injection technology.

Oscilloscope/Multimeter Integration:

Utilize an oscilloscope and multimeter for comprehensive diagnostic and measurement functionalities.

Banana Connector Connectivity:

Connect to the system's parameters through the integrated banana connector, allowing efficient measurement of electrical signal parameters for each system component, including sensors and actuators.

Control Unit Diagnosis:

Conduct control unit diagnosis through the OBD 16-pin diagnostic connector.

Perform electronic control unit (ECU) identification.

Read and erase fault codes for effective troubleshooting.

Display live data of the operating system parameters.

Activate actuators based on the control unit's specifications.

Encode and configure the control unit as needed.

Closed Structure Design:

The stand features a closed structure, ensuring that internal wiring is not visible, providing a neat and organized appearance.

-

Closed Structure Design:

- The stand is thoughtfully designed with a closed structure, ensuring that internal wiring remains discreet and is not visible. This design enhances both aesthetics and safety.

-

Power Supply:

- Dual power supply compatibility: 220 V and 12 V, providing flexibility for various operating environments.

-

Dimensions (approx.):

- Electronic Part (Board): 1820 x 1360 x 500 mm

- Mechanical Part (Trolley): 1500 x 800 x 500 mm

-

Net Weight (approx.):

- The stand has a manageable net weight of approximately 135 Kg, allowing for ease of mobility and setup.

-

Origin:

- Proudly manufactured in the European Union (EU), ensuring quality craftsmanship and adherence to European standards.

-

Certification:

- Holds a CE certificate, affirming compliance with European safety and quality regulations.

Discover the convenience and quality of our stand, meticulously designed for efficiency, safety, and reliability. The closed structure conceals internal wiring, and with dual power supply options, it provides adaptability to different power configurations. With dimensions catering to both the electronic and mechanical parts, as well as a reasonable weight, our stand is a versatile and CE-certified solution made in the EU.

► Examination console for 10 hidden fault simulations

► Automotive oscilloscope

► OBD diagnostic scan tool

Automotive training equipment is a great tool for professional teachers and technicians that helps explain to students of technical subjects how processes in Diesel engine control system CR/EDC 15 operate and its technology.