- Home

- Who We Are

- Products

-

Brands

-

Products by Measure

- Vibration Analyzers

- Peristaltic Pumps

- Airflow

- CO Carbon Monoxide

- Geiger counters

- Destiladores

- Spectrophotometry

- Sterilization

- Fluorescence

- GEOTECHNICS

- Soil Moisture

- Leaf area index

- Rain Gauge

- Meteorology

- Water Level

- O2 Oxygen

- pH

- Differential Pressure

- Radiation

- Salinity/Conductivity

- Telemetry

- Air Speed

- Relative Humidity

- Veterinary

- FUEL CELL HARDWARE

- Network Analyzers

- Calibrators

- WATER FLOW

- Color / Colorimeter

- Particle Counters

- Wind Direction

- Spectrometry

- Evapotranspiration

- Photosynthesis

- Cracks in Buildings

- Pipes Inspection

- Quantum Light

- Movement & GPS

- Diesel Level

- Oxígeno Disuelto DO

- Atmospheric Pressure

- Radon

- Sap/Sap Flow

- Temperature

- AIR QUALITY

- Ammonia

- Chlorophyll

- Conductivity in Soil

- Dendrometers

- Electrochemistry

- Spectroradiometry

- Pharmacy & Medicine

- GAS (ANALYZERS)

- Leaf Wetness

- Idc (DC Current)

- KW & KW/H

- PAR Light

- Nitrate

- Occupation and Time

- Particle Meters

- Soil Water Potential

- Pulses

- Flavor/Taste/Acidity

- Sodium

- Turbidity

- VOC

Scientech2470 Electro Pneumatic Workbench

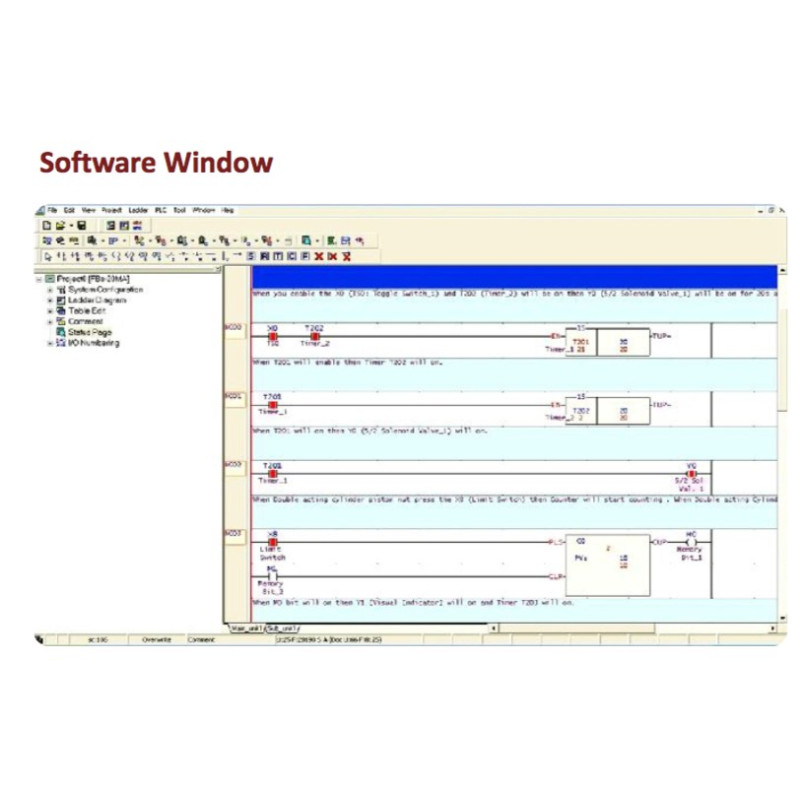

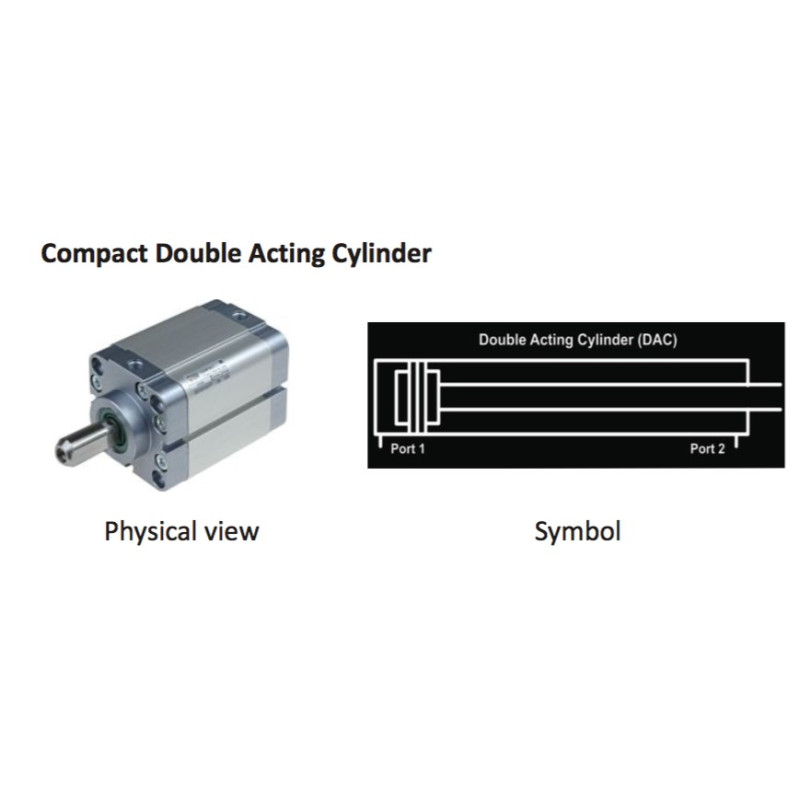

The Scientech 2470 Electro-Pneumatic Workbench is designed to demonstrate the design, construction and application of pneumatic components and circuits. Integrates PLC technology to build hybrid industrial automation systems with pneumatic components and modules.

Scientech 2470 Electro Pneumatic Workbench is designed to demonstrate the design, construction and application of Pneumatic components and circuits. It integrates PLC technology to build Hybrid Industrial Automation systems with Pneumatic components and modules.

Pneumatic technology is found in numerous areas of engineering. Students investigate the basic “building blocks” of modern Pneumatics and how they are interconnected to for m systems. Pneumatic Systems provide the power needed to control aircrafts, operate heavy dump trucks, excavators, operate the brakes in our cars and even power lifts in tall buildings.

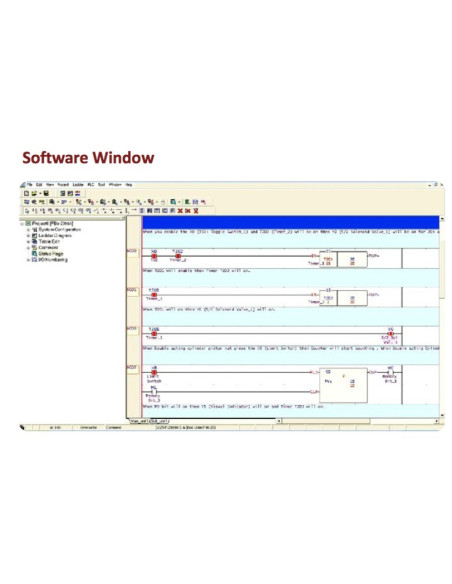

PLC provides flexibility to design and build numerous systems using software and I/O inter faces without changing hard wired connections.

- PLC operated Electro Pneumatic platform

-

12 Digital Inputs, 8 Digital Outputs

-

Open platform to explore wide PLC and Pneumatic applications

-

Industrial feel & look

-

DIN rail mounting for PLC

-

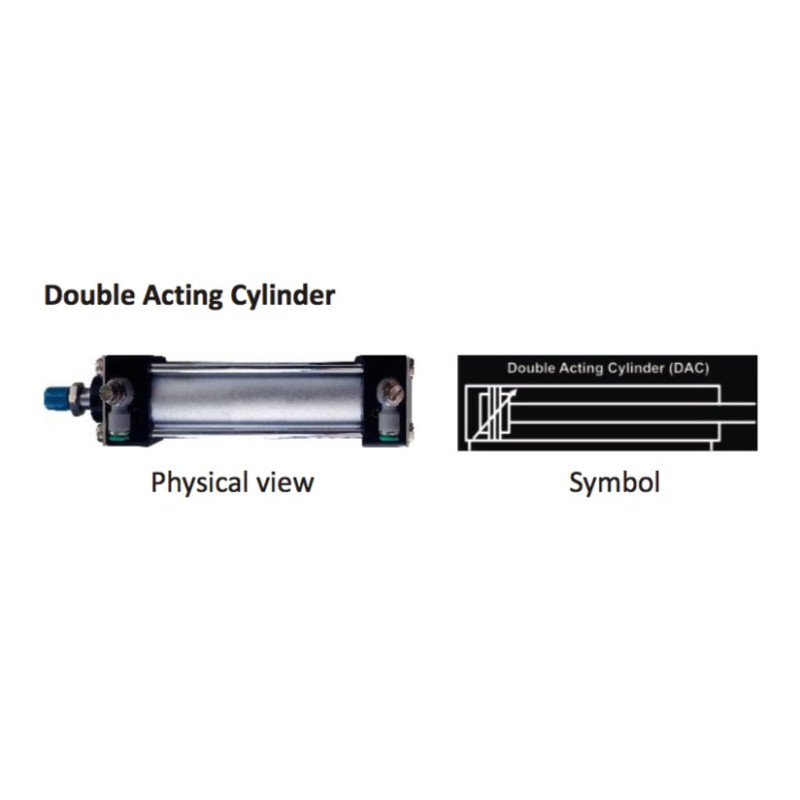

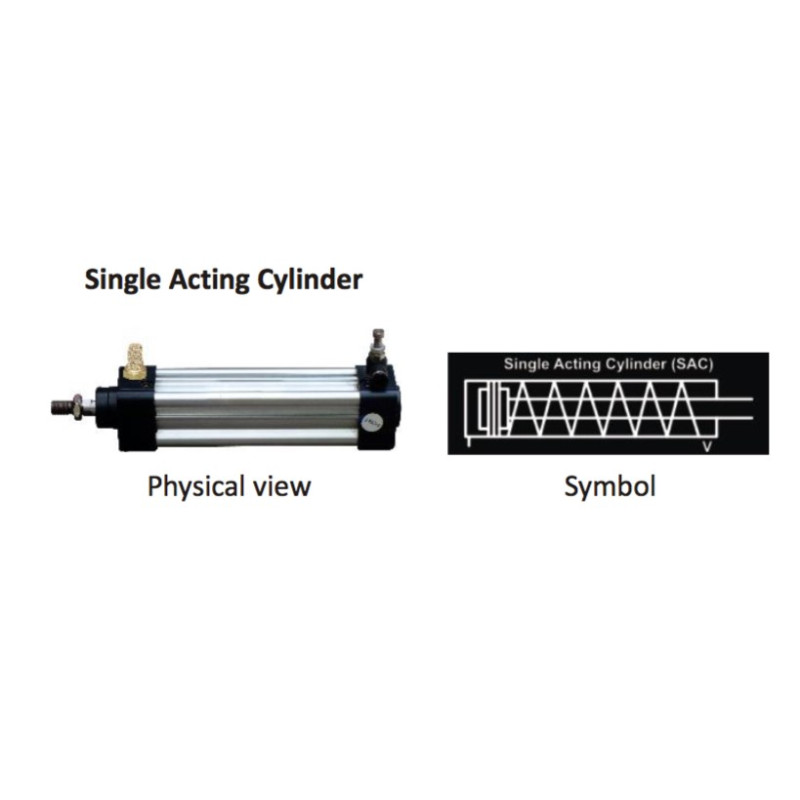

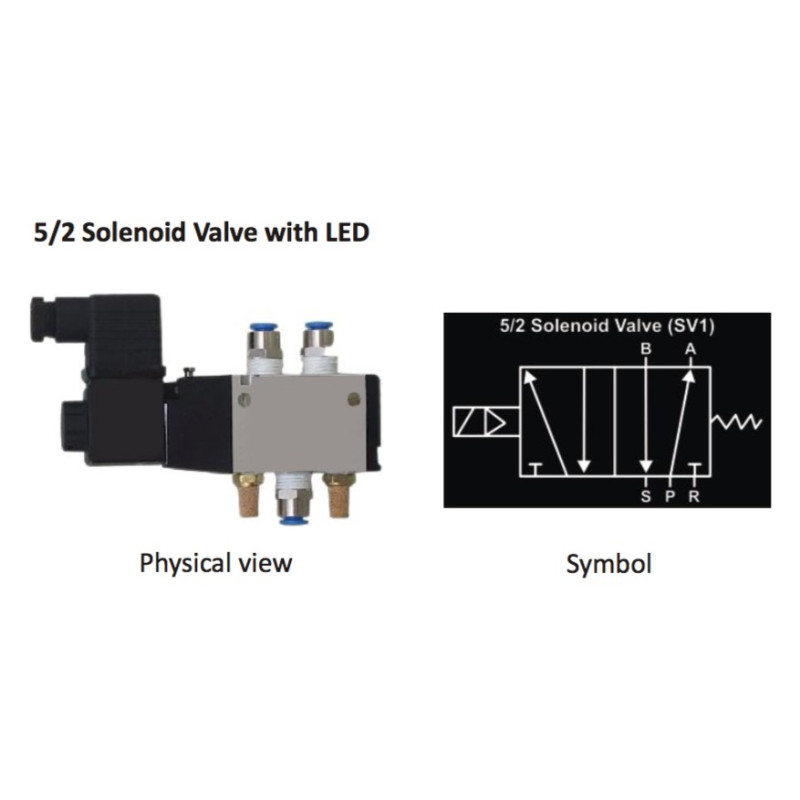

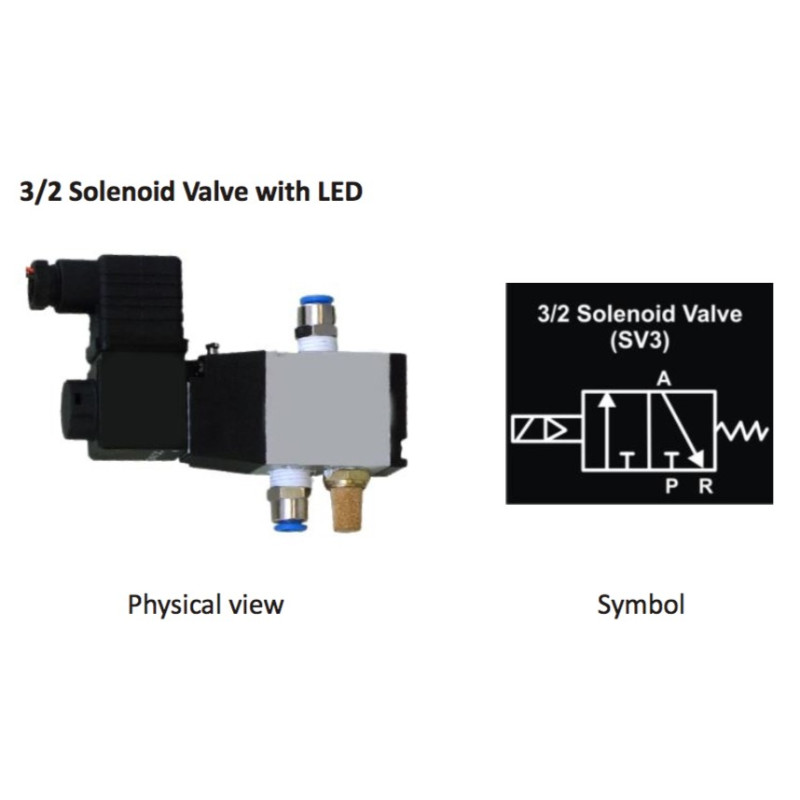

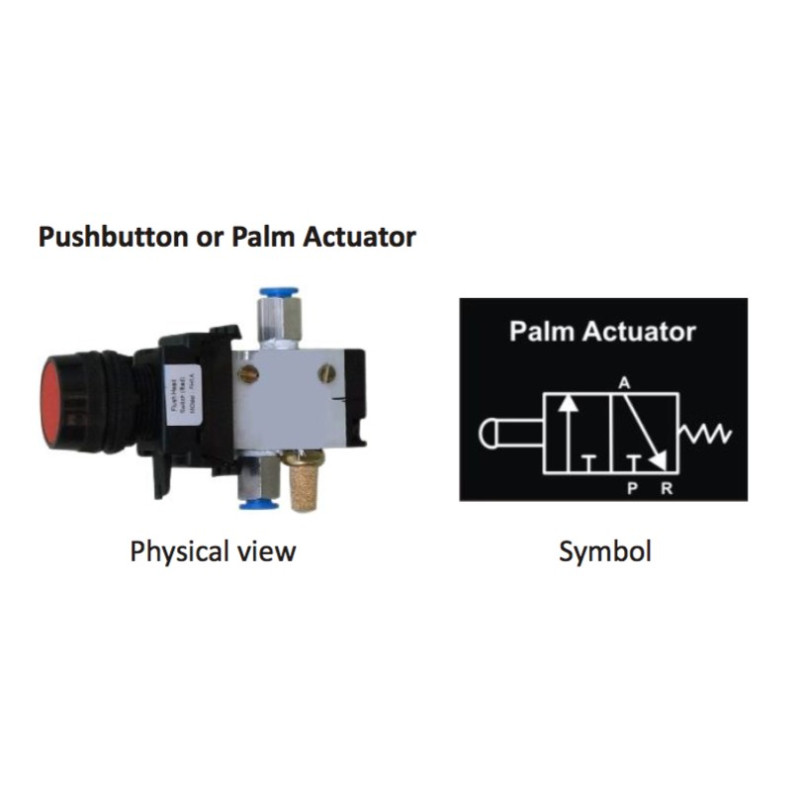

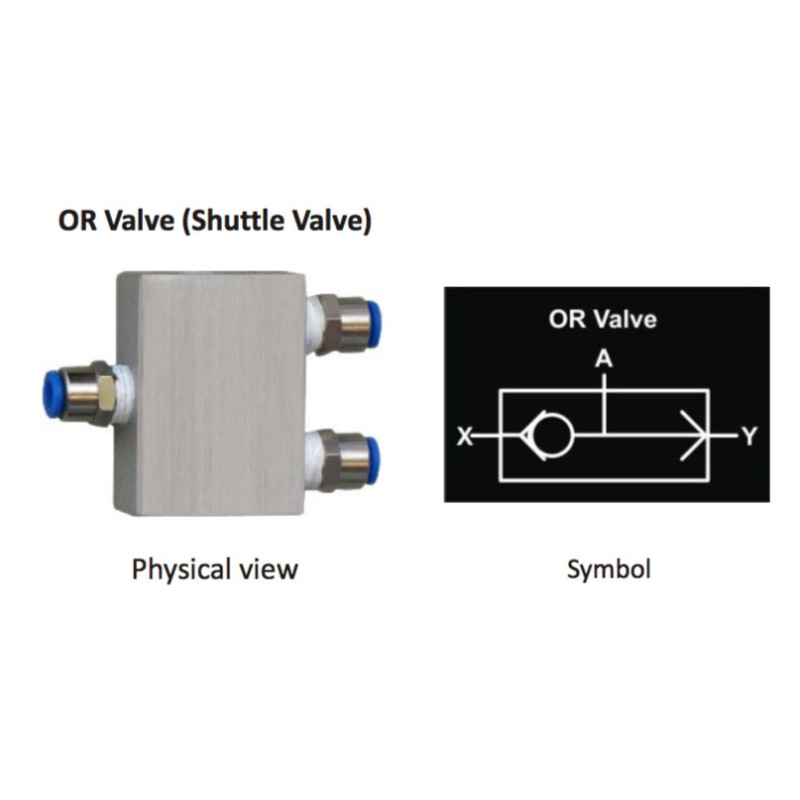

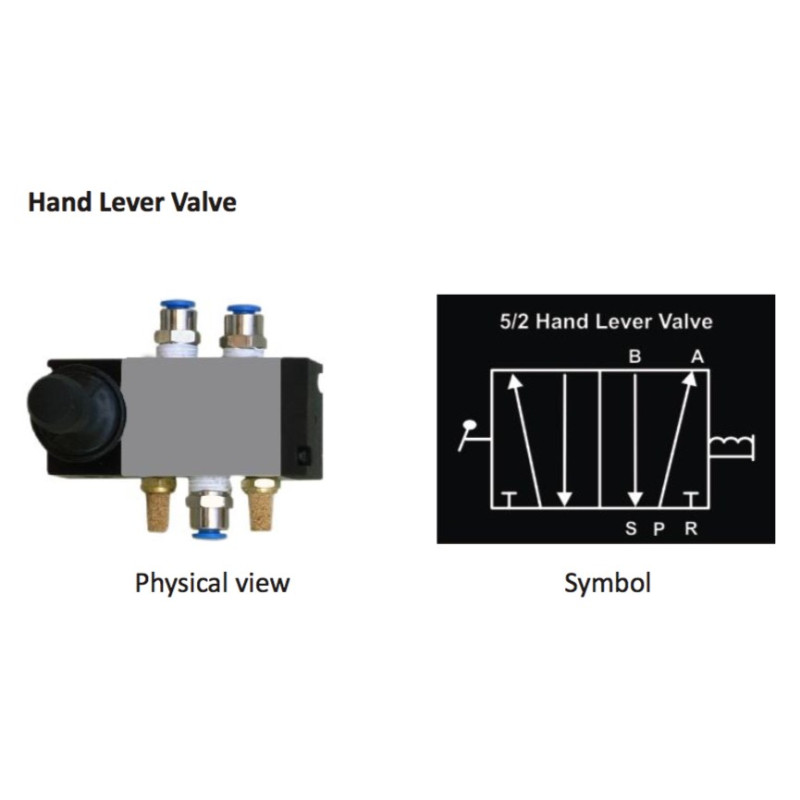

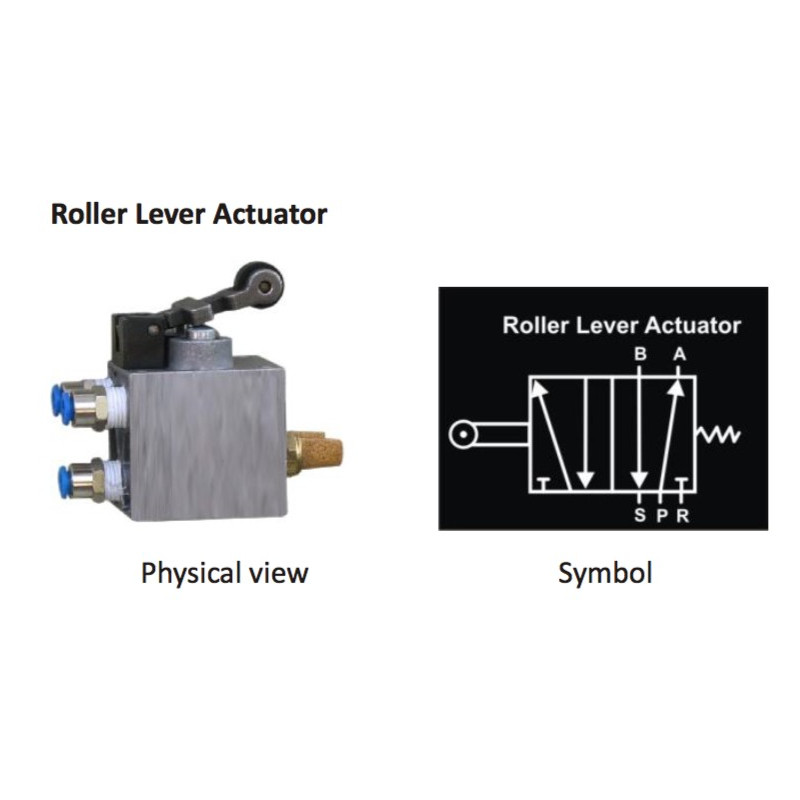

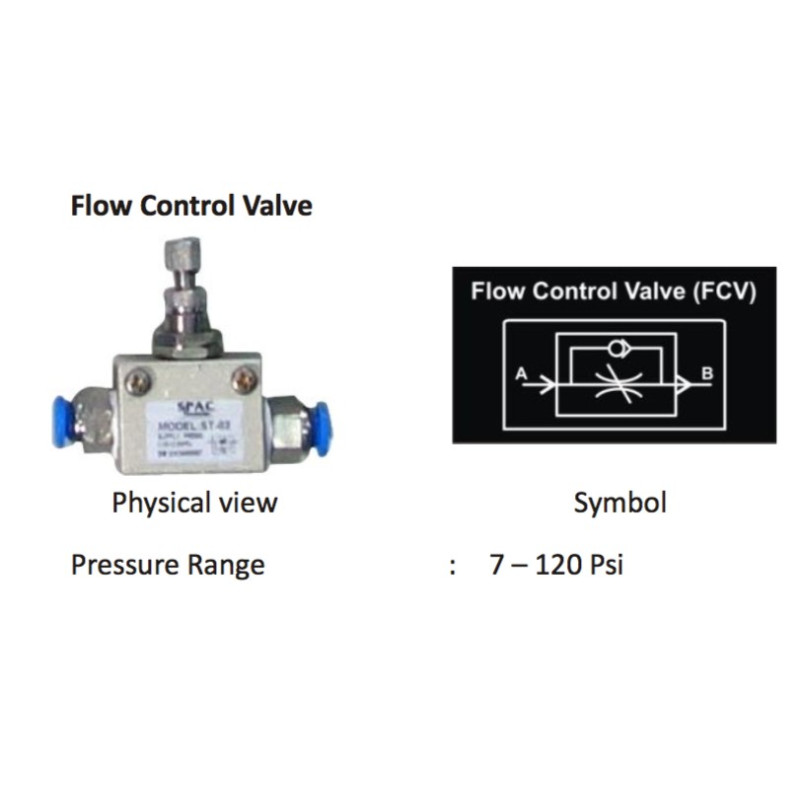

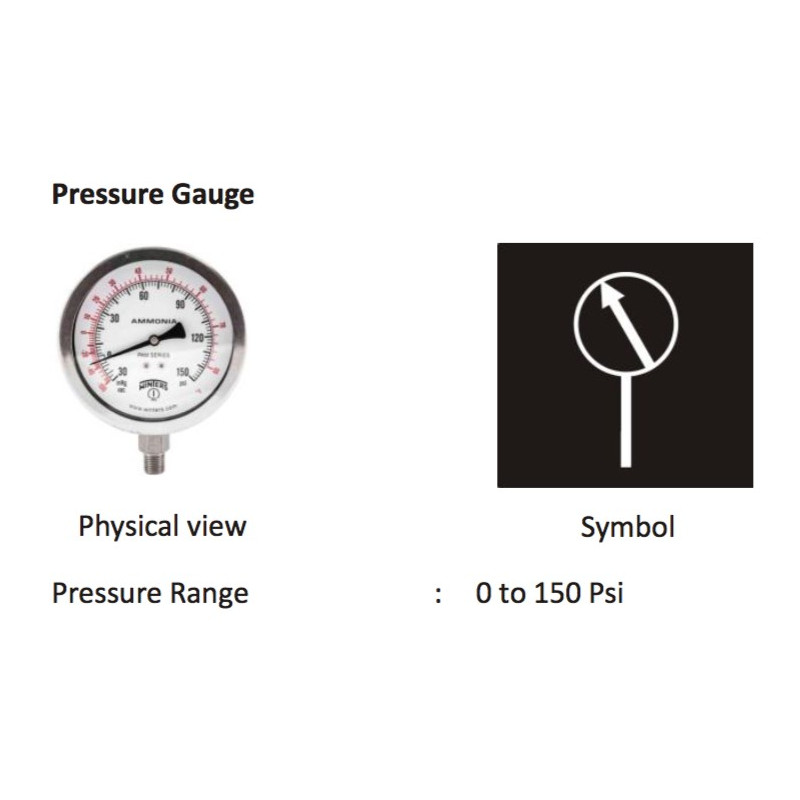

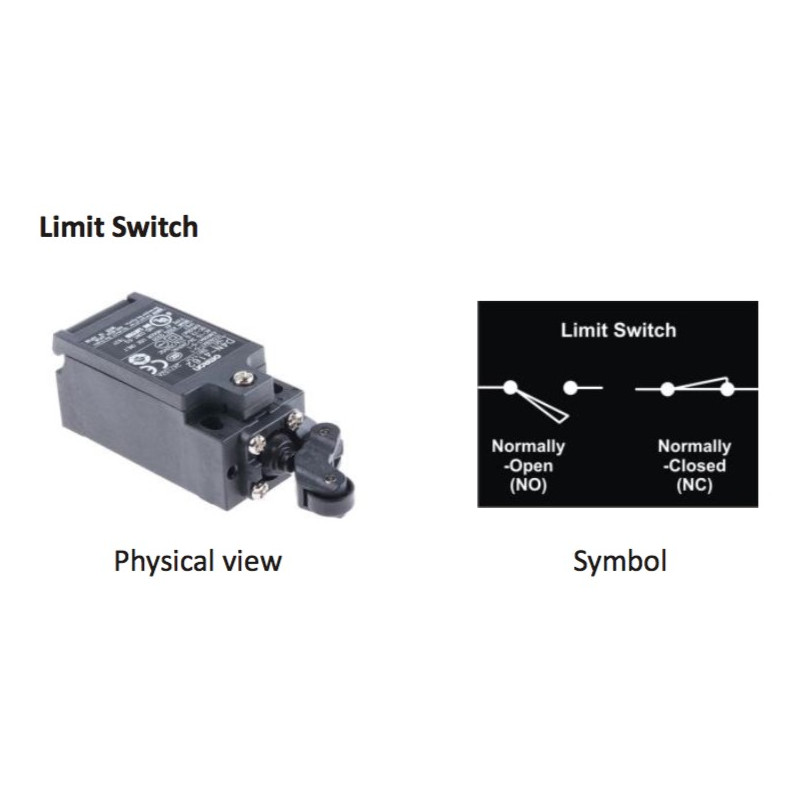

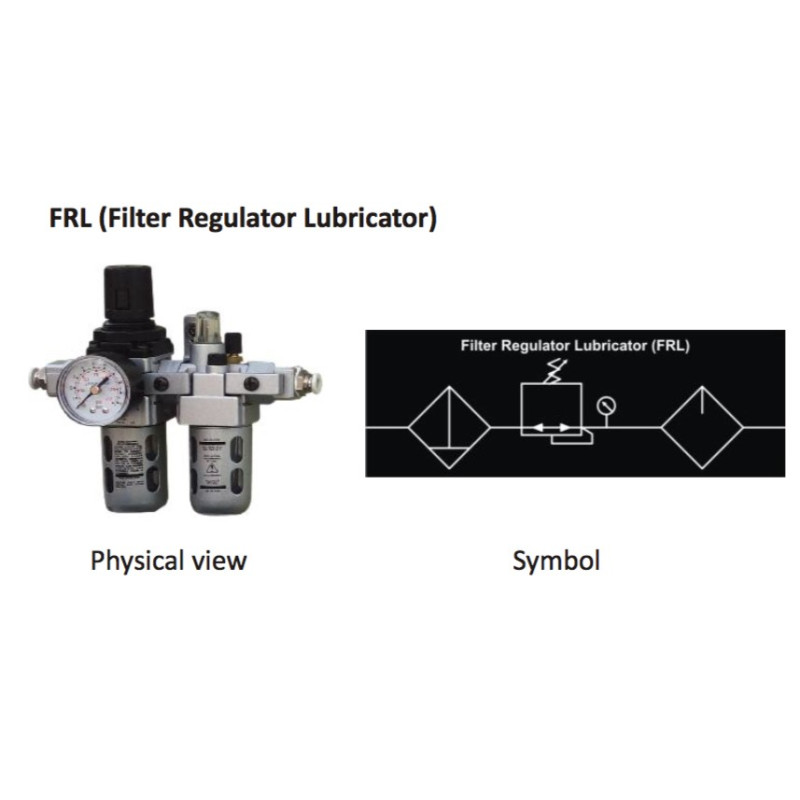

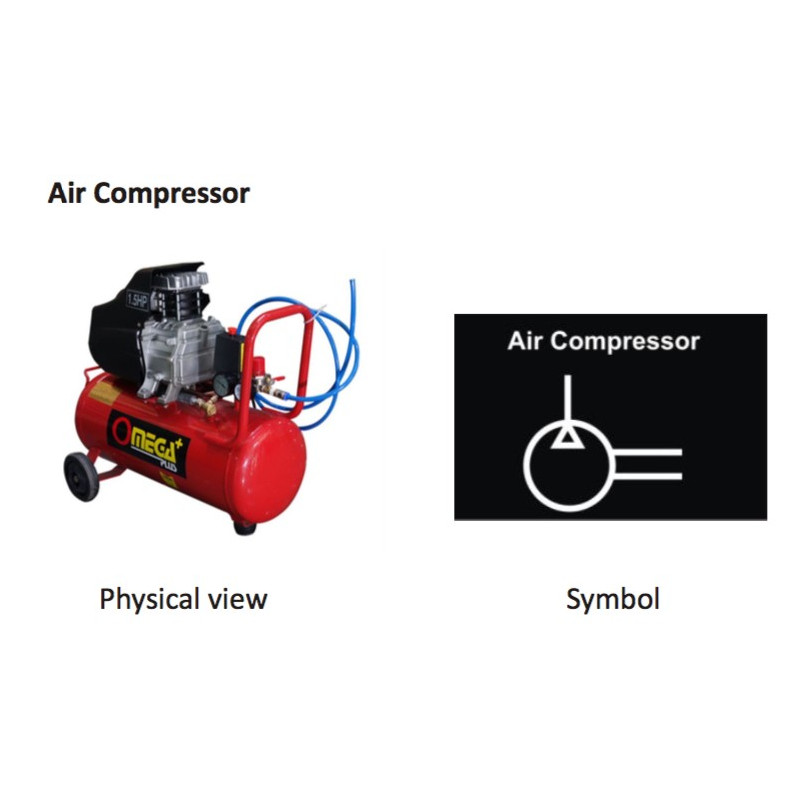

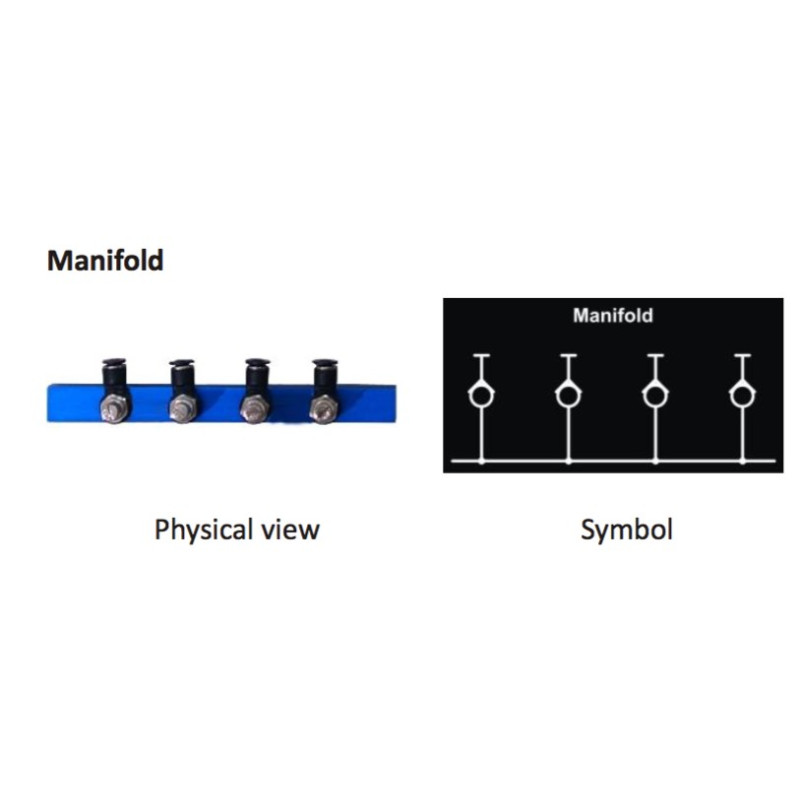

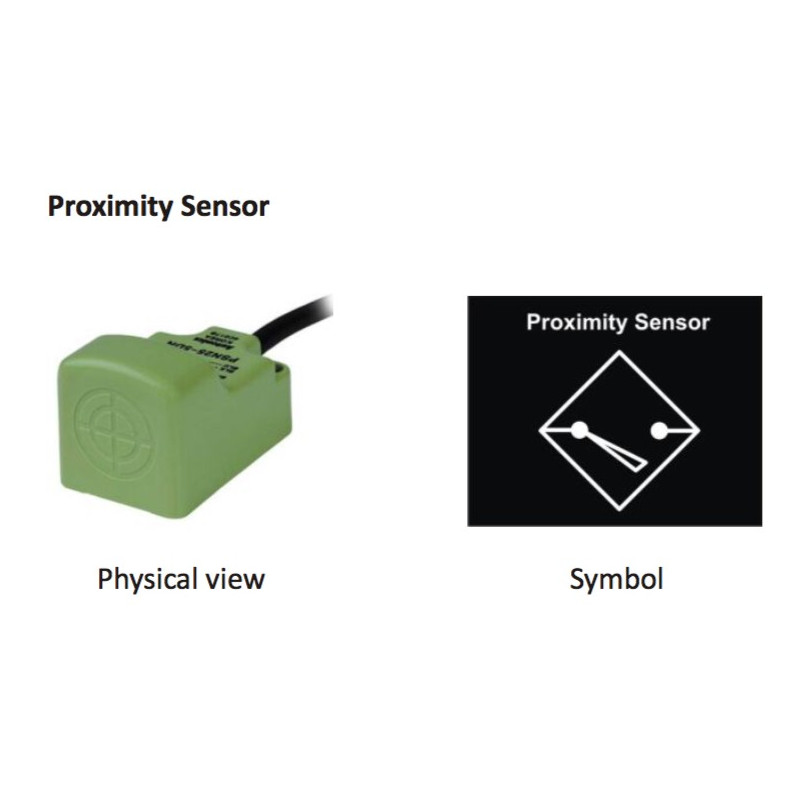

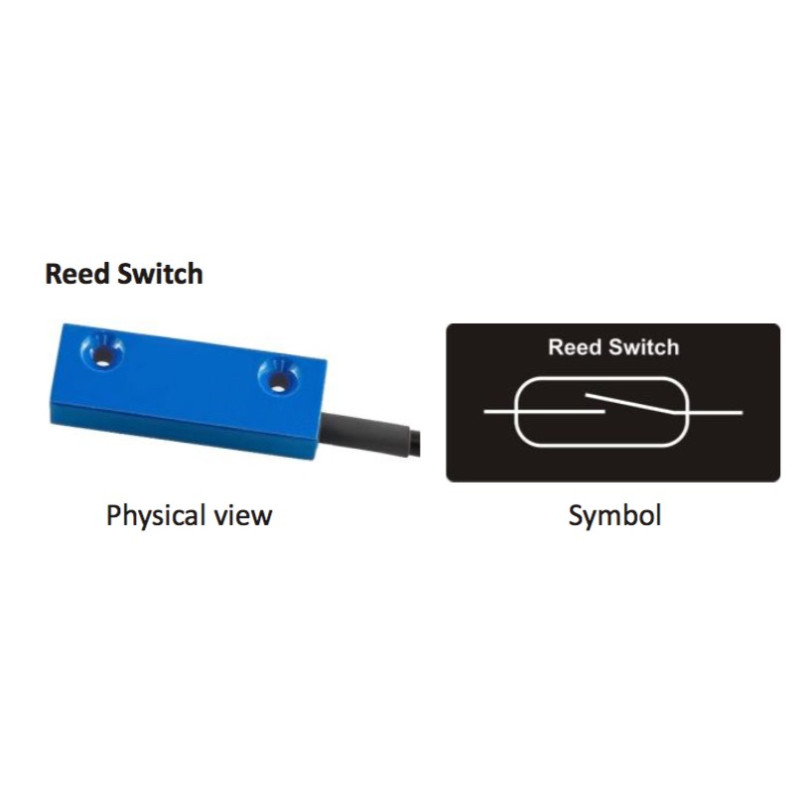

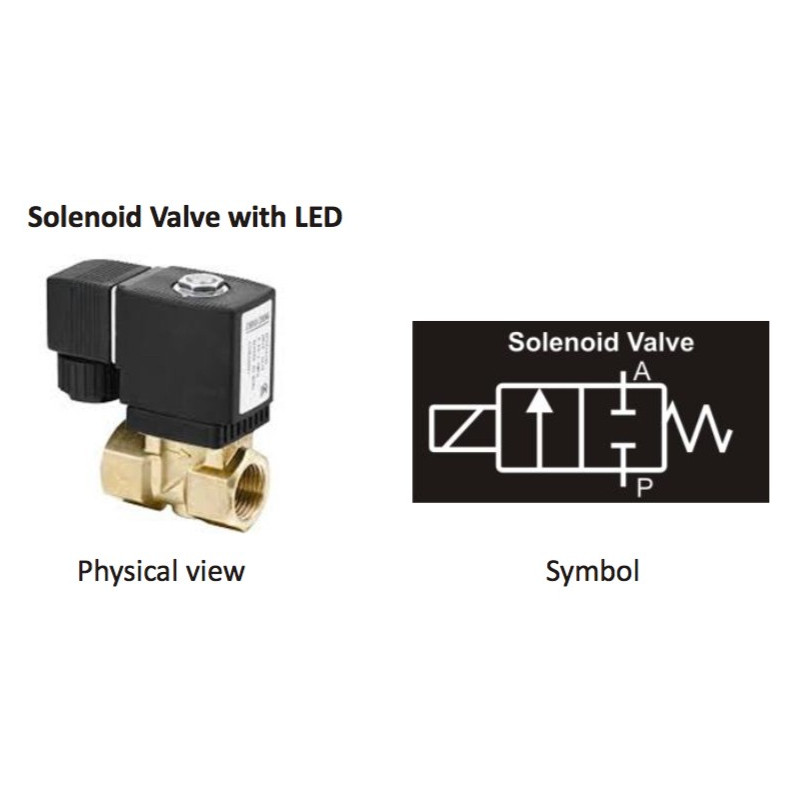

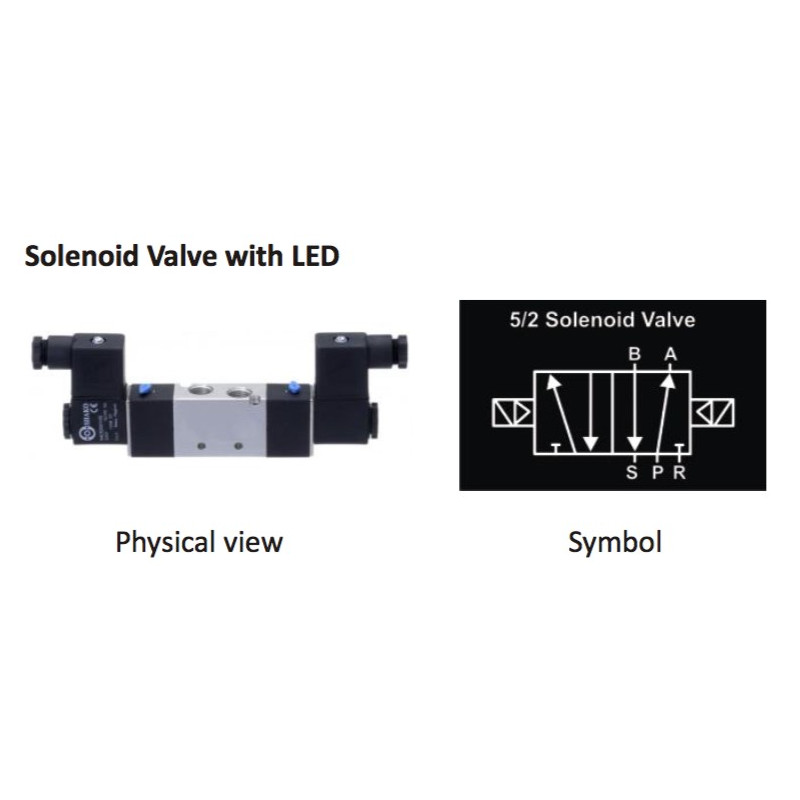

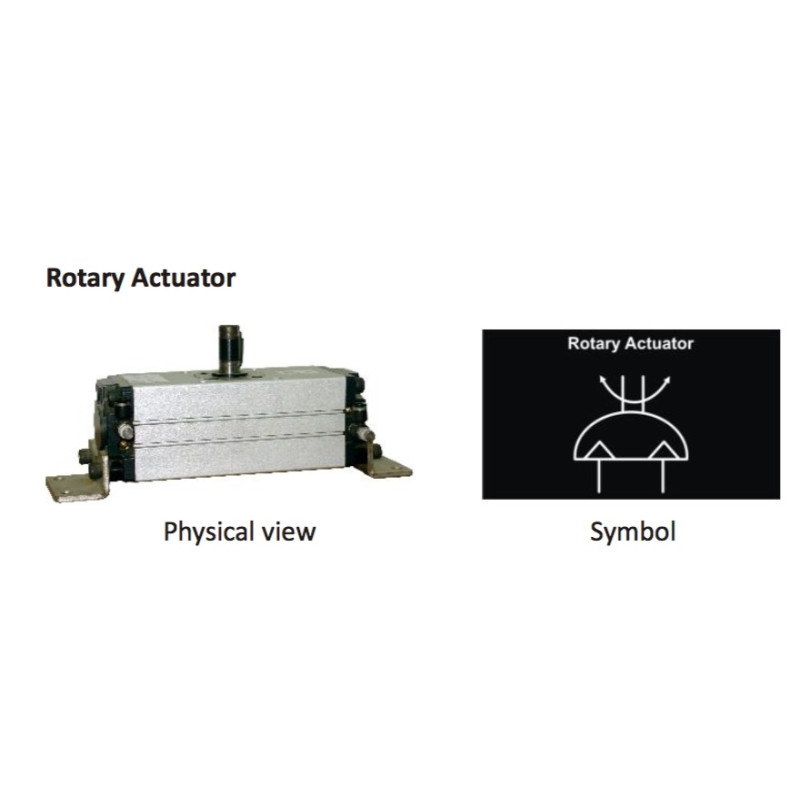

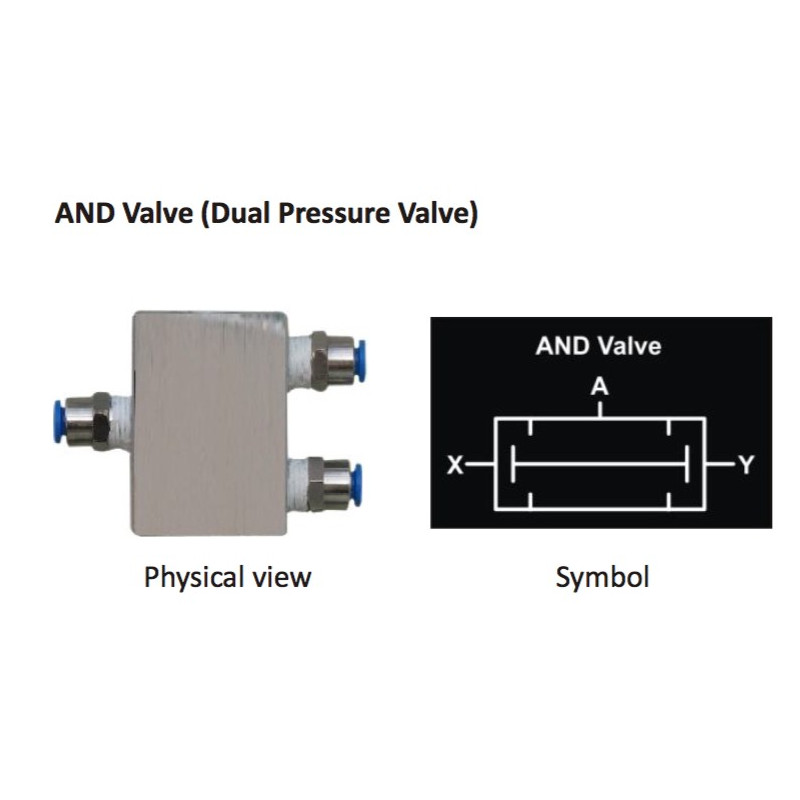

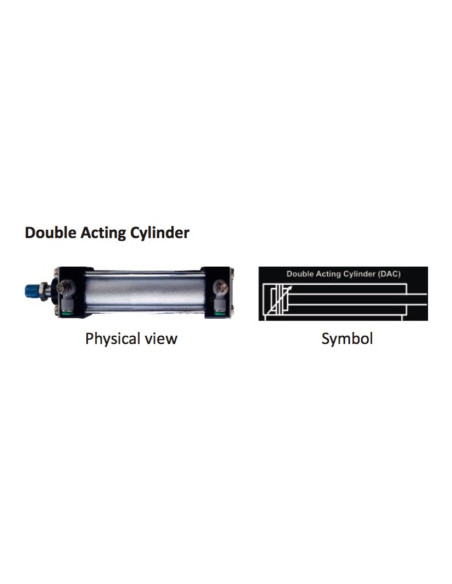

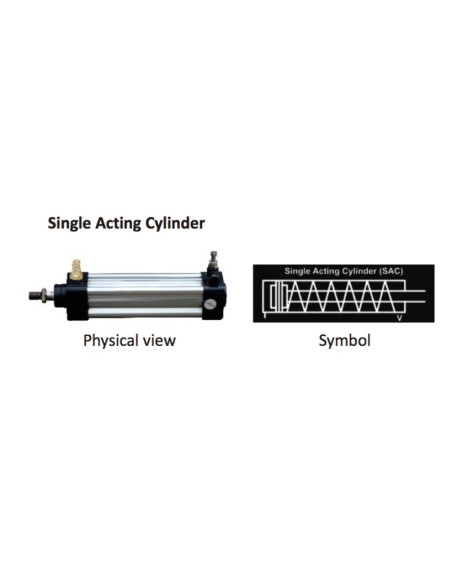

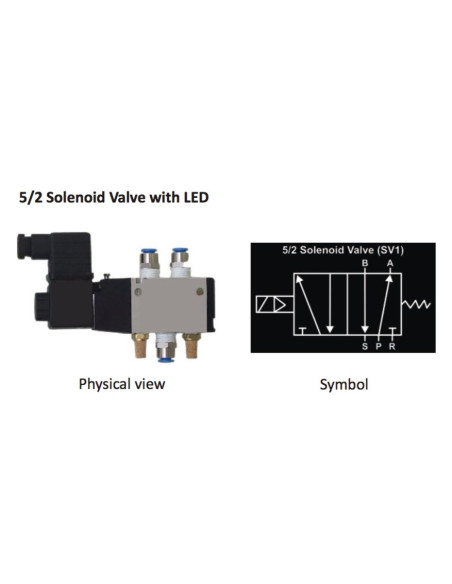

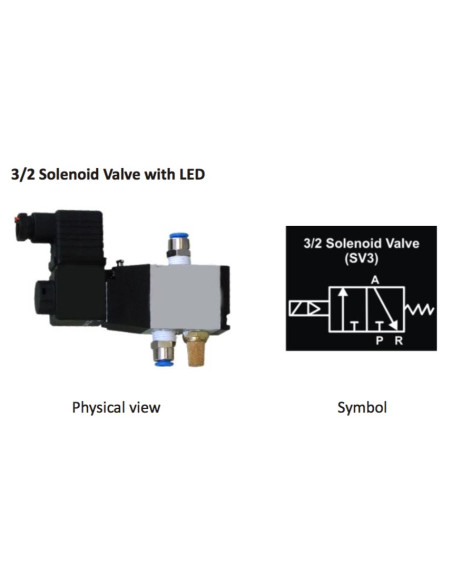

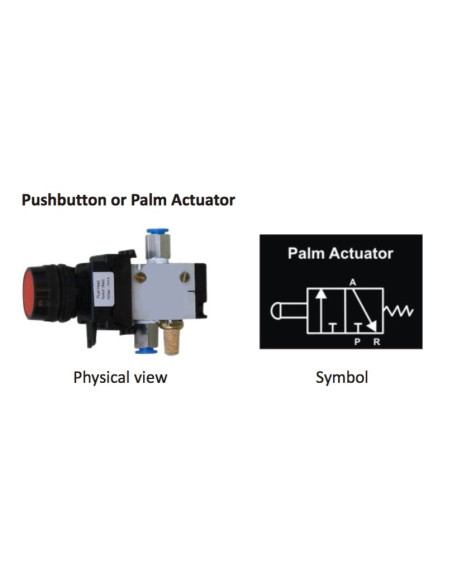

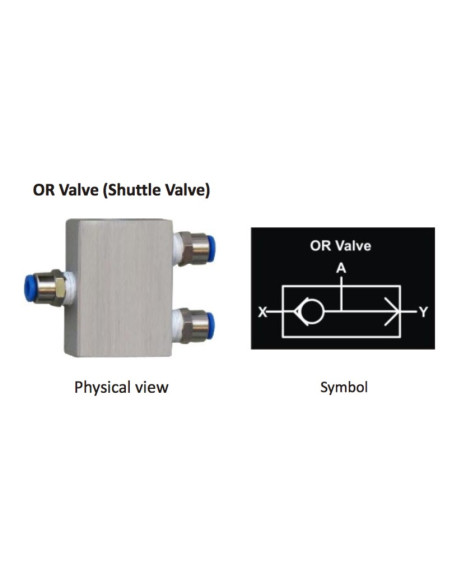

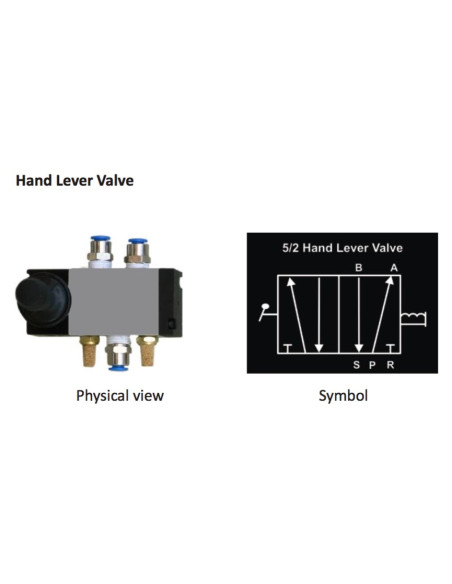

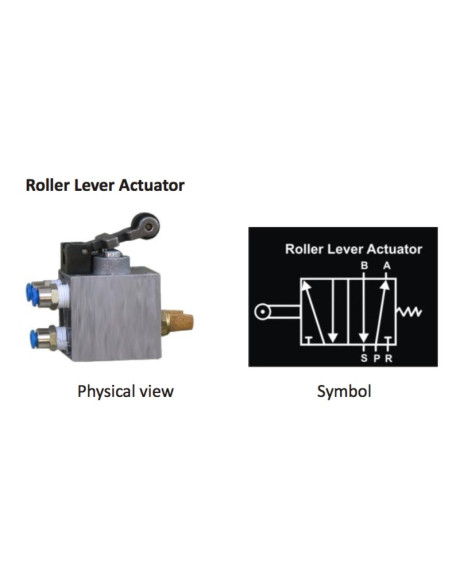

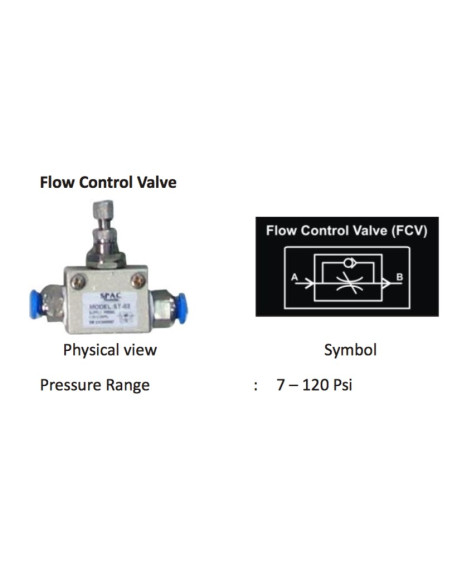

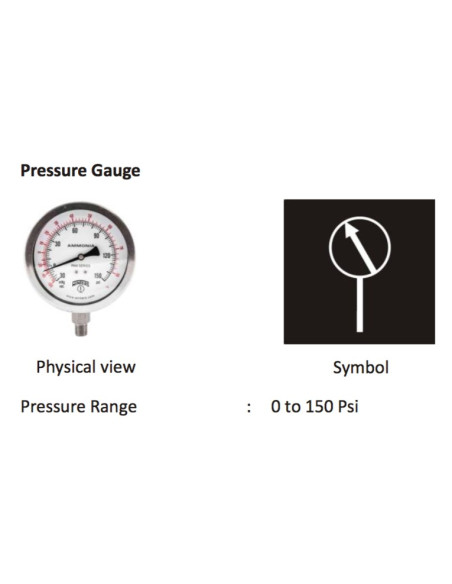

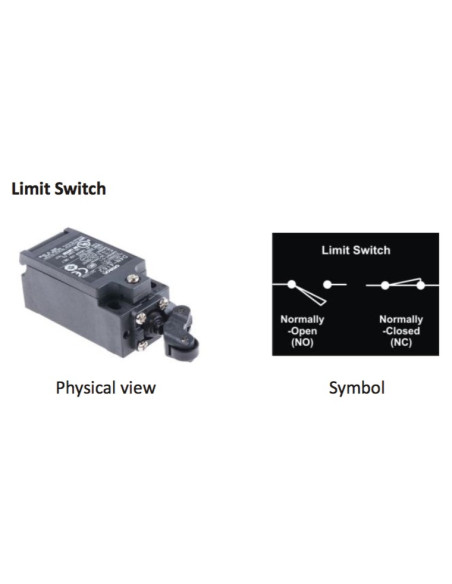

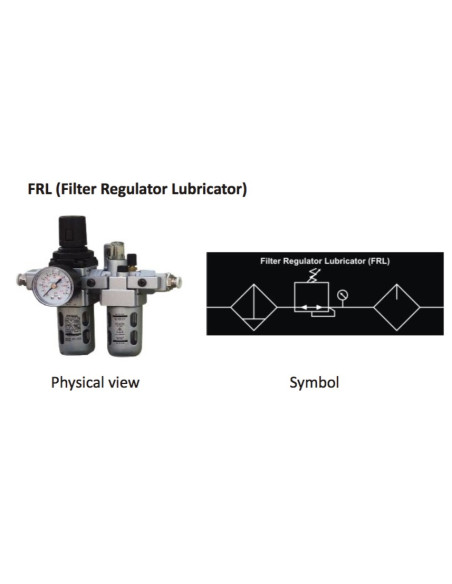

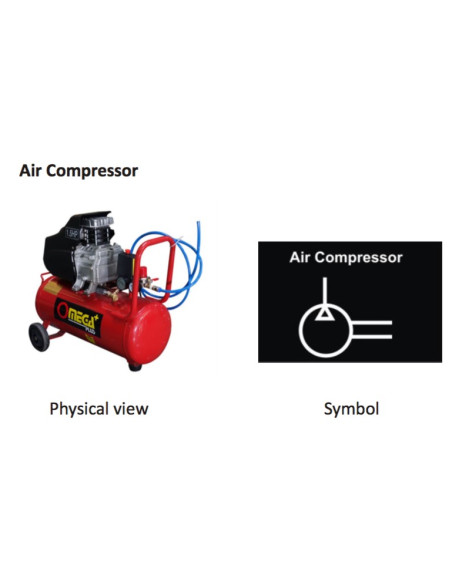

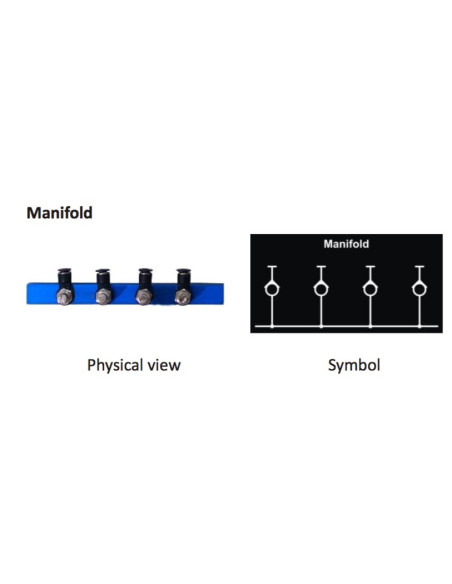

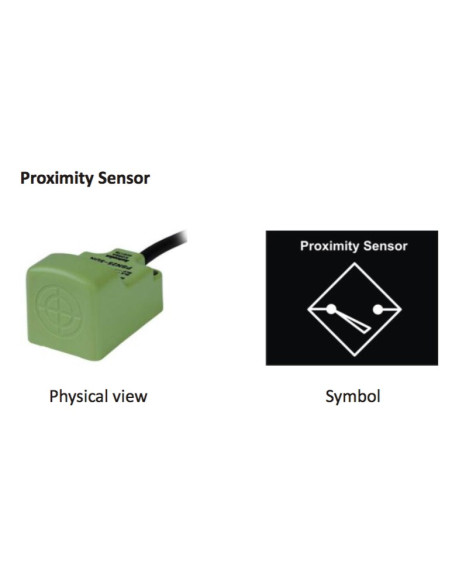

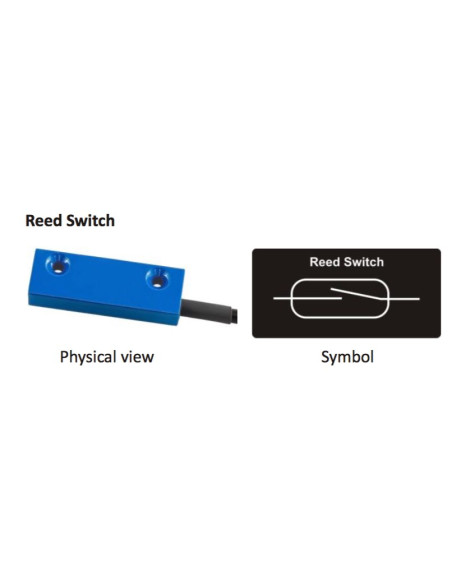

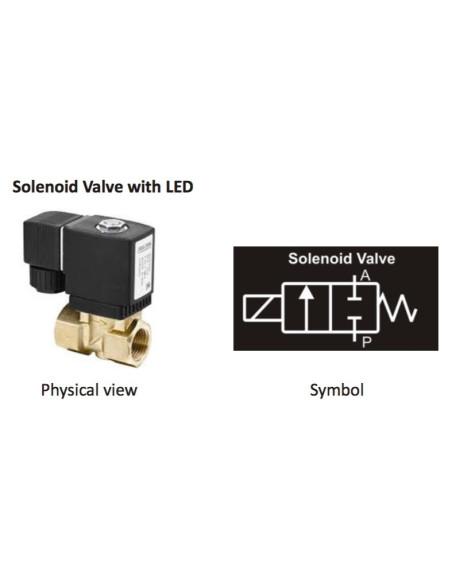

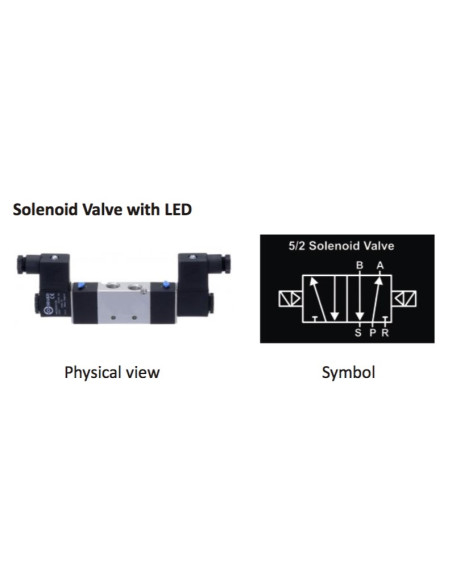

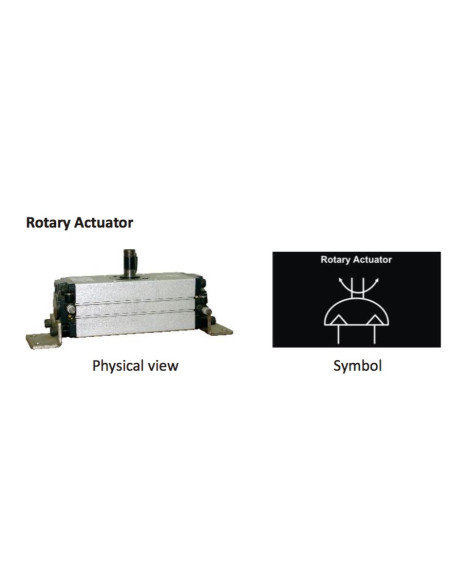

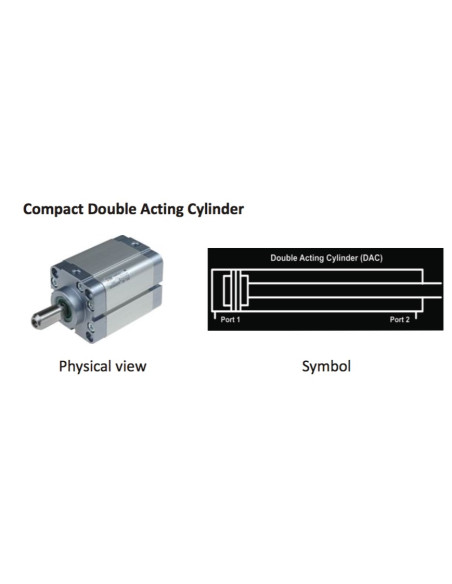

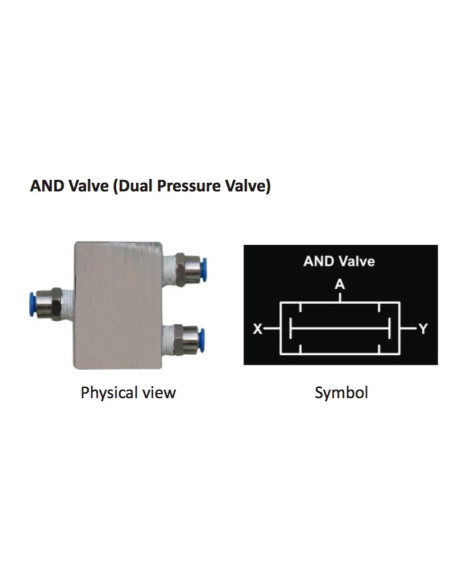

Function and identification of Pneumatic components and their symbols

-

Powerful instruction sets

-

High execution speed

-

Extremely easy and student friendly software

-

Several sample Ladder programs

-

Practice troubleshooting skills

-

Extensive Learning

-

Workbench has 4 wheels, for suitable movement and installation

-

Robust constr uction

-

Toggle switches, LEDs, buzzer , double acting cylinder , solenoid valve, flow control valve, manifold, hand lever valve, limit switch, proximity sensor , IR sensor , palm actuator , AND valve, OR valve, roller lever valve, FRL, pressure gauge, TEE, single acting cylinder, and air compressor

-

Board to attach documents

-

4 mm patch cord connections

-

Mounting panel for Pneumatic Components

-

Two storage drawers with locking facility, Place in drawers for meters, patch cords, components, bread board and other accessories for storage, and easy identification.

-

MCB for ON/OFF control and over load protection

-

P rovision for PC – CPU

-

Sequential & Linear P neumatic control

-

Understanding of Industrial P neumatic Components

-

Pneumatic safety awareness

-

Online product tutorials

Scope of Learning:

Study and use of :

-

Ladder Programming

-

Normally Open bit (NO) and Normally Close bit (NC) instruction by PLC

-

Logic gate e.g. NOT, AND, OR, NAND, NOR, XOR, XNOR

-

Memory bit

-

Set & Reset bit

-

Special Memory bits

-

Timer instruction

-

Cumulative Timer instruction

-

Counter instruction

-

UDCTR instruction

-

PWM instruction

-

Compare instruction

-

Arithmetic function (addition)

-

Trigonometric function (Sine instruction)

-

Move instruction

-

Conversion (BCD to Binary instruction)

-

Jump & Label instruction

-

Master control loop

-

Skip control loop

-

Subroutine

-

Fundamental principle of Pneumatics and its application

-

Air compressor

-

Sensor & Actuator

- Category

- Electro-Pneumatics